-

- Back

-

- Back

-

- Back

-

- Back

-

- Back

-

- Back

-

- Back

-

- Back

Patents On Polyester Resin Matrix Flooring Tiles

Patents On Polyester Resin Matrix Flooring Tiles

Patents On Polyester Resin Matrix Flooring Tiles

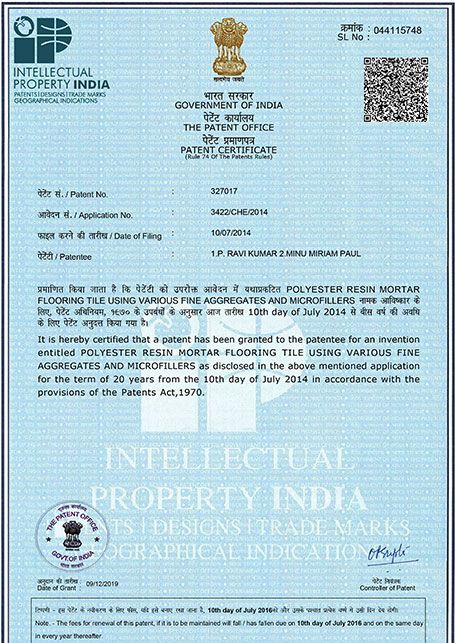

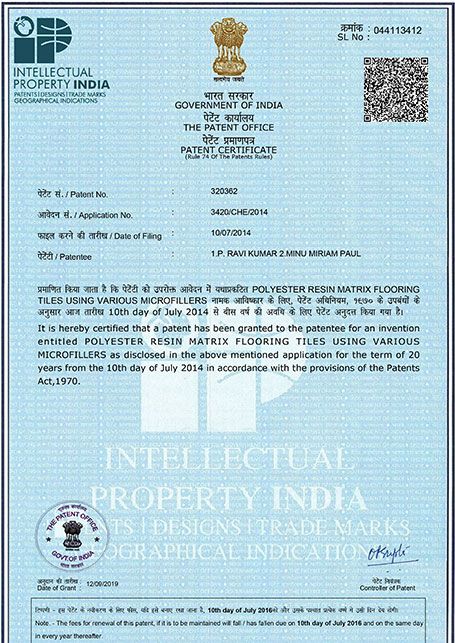

PATENTS ON POLYESTER RESIN MATRIX FLOORING TILES USING VARIOUS MICRO FILLERS & POLYESTER RESIN MORTAR FLOORING TILES USING VARIOUS FINE AGGREGATE AND MICRO FILLERS

Mr. P. Ravikumar, Associate Professor, Civil Engg. & Mrs. Minu Miriam Paul, Research Scholar has obtained dual Patents on “Polyester Resin Matrix Flooring Tiles Using Various Micro Fillers”&“Polyester Resin Mortar Flooring Tiles Using Various Fine Aggregate and Micro Fillers”.

“Polyester Resin Matrix Flooring Tiles Using Various Micro Fillers”relates to polyester resin matrix mix using micro fillers such as fly ash, and ground granulated blast furnace slag-based flooring tiles. The composition for a polyester resin matrix using fly ash, ground granulated blast furnace slag, crusher dust wherein the micro filler: resin (MF:R) and the percentage of resin content by weight of both the material taken together is optimized for compressive strength. The process of obtaining the mix proportion and making mix with catalyst and accelerator is based on void content. The product of tile is proposed from the composition which is different from the ordinary furnace backed clay tiles. It requires only the room temperature curing and also reduces Co2emission. This type of tile can be manufactured anywhere as per the requirement and need. This method is used to have a workable, cast able mix for different combination of micro fillers which is available waste for the application of flooring tiles.

Similarly, “Polyester Resin Mortar Flooring Tiles Using Various Fine Aggregate and Micro Fillers” relates to polyester resin mortar mix such as different gradation of fine aggregate and fly ash, ground granulated blast furnace slag as micro filler-based flooring tiles. The composition of a unsaturated polyester resin mortar using two types of micro fillers wherein micro filler: resin (MF:R), coastal sand, eco sand as fine aggregate, wherein fine aggregate to micro filler ratio and percentage of resin content, micro filler content, fine aggregate content by weight of all the material taken together is optimized for compressive strength. The product of tile is proposed from the composition which is different from the ordinary furnace backed clay tiles. It requires only the room temperature curing and also reduces Co2emission. The advantage of this type of tile is to be manufacture anywhere as per the requirement and need. This method is used to have a workable, cast able mix for different combination of locally available sand and different micro fillers which is the available waste for the application of flooring tiles.